ABUS EOT cranes for Niehoff, a wire and cable machinery manufacturer

You might need up to a dozen machines to run through a coil with copper wire thick as a finger to end up as coated and shielded cables fit for data transfer. The production of such cables requires understanding of materials science, knowledge of process engineering, and expertise of material processing. There is no other company with such mastery in the production of the machinery required in this process as the German company Niehoff (www.niehoff-gmbh.info). Machinery for wire and cable production is distributed worldwide from their headquarters in the Middle Franconian town of Schwabach.

Wire made by Niehoff machines is used in many areas of the industry: you might find it in the wire frames of your glasses or in your garden fencing systems. Niehoff has also developed and built various processing machines for the cable industry. Galvanic wire plating lines use galvanic processes to apply thin coats of other materials onto wire for example. The Niehoff portfolio also includes suitable spoolers and coilers to reel up the finished wire products. This enables Niehoff to supply the entire range of machinery required by wire and cable manufacturing industries.

The origins of the company go back to the year 1859 when the production of simple wire drawing machines began in Schwabach. Today Niehoff employs over 400 staff at their headquarters. The company used to be in the town centre where it was not possible to enlarge the production and administrative buildings. Thus the move was made in three construction phases to relocate to an area of 88,000 m² on the outskirts of Schwabach in recent years. The first construction phase saw the building of new production plants.

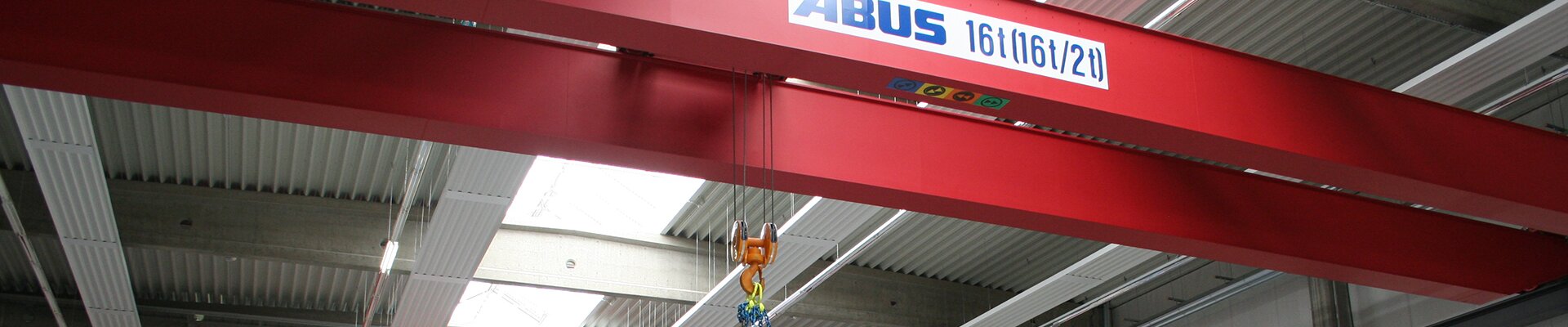

The former production plant employed light weight cranes and EOT cranes of different brands. However, the material flow solution for the new plant was to come from one provider. Crane systems were needed in order to install and to move the different wire drawing machines. Niehoff consulted with staff in great detail and was also assisted thoroughly by the ABUS agent, then came to the conclusion that 16 EOT cranes were to be installed during the first construction phase. These were 8 double girder cranes and a further 8 single girder cranes. During the planning phase Niehoff defined in-house standards so that it would be possible in future to move cranes around the factory should the need arise. There are only two spans for cranes, 17.2 m for small bays and 24.2 m for wider bays. All single girder EOT cranes have maximum load capacities of 10 tonnes whereas the double girder EOT cranes boast SWLs of up to 16 tonnes. All supporting structures were designed to cope with loads of 16 tonnes. All hoists feature mostly identical optional accessories, e.g. frequency converters ABULiner. The ABULiner enables cranes and hoists to smoothly accelerate and decelerate and to travel at infinitely variable speeds. All cranes are fitted with identical radio remote controls. Nearly all areas of the production plant use more than one crane on the same crane track, therefore photoelectric collision protection devices were installed on the cranes. When two cranes approach the travel speed is slowed down then shut off completely. Niehoff uses containers for worldwide shipping of the completed machines. For this reason the in-house standards had to be amplified: the pair of cranes dedicated to the internal transport of overseas shipping containers is operated via tandem control. Thus one single radio remote control operates two cranes in parallel which makes for safe transport.

One other feature has been included in the design too: all single and double girder EOT cranes have an auxiliary hoist with 2 tonnes SWL in addition to the main hoist. This important technical detail takes into account the flexible use of the production bays. Completed machines are moved using the main hoist for example when they are tested. Individual parts for example for installation use the auxiliary hoist. The handling of individual parts is thus simplified not only because of greater speeds available but also because ropes and hooks are dimensioned in such a way as make them easier to manipulate. The main hoist not being used for installation works of inferior loads means that working hours are adding up much slower which in turn reduces maintenance costs.

The ABUS cranes are used in different areas in the production and in the test area—and they are painted copper red, a tribute to the material most used at Niehoff’s.