Swedish manufacturer uses ABUS HB systems for excavator components

The human wrist is a highly complex articulated structure being capable of a great variety of functions. Exact interaction of the individual joint parts makes this multifunctionality possible. A person can turn the wrist, tilt it at different angles, and use it as stabilising or propping element depending on the task to be performed.

The Swedish company Engcon (www.engcon.com) took this image of the multifunctional wrist and—with much ingenuity and driven by the desire to design and produce efficient system components for excavators—translated it into the tiltrotator, the “wrist” of the excavator. The tiltrotator allows the excavator to rotate the bucket unhindered around its axis, i.e. 360°, and the bucket can also by tilted by up to 45°. The complete range of tiltrotators is available for all types of excavators in the load capacity range between 1.5 and 32 tonnes. The tiltrotator—whether newly purchased or retrofitted—is also the wrist, the joint in between, for a great range of accessories and auxiliary products to be fitted to the excavator thus optimising the tasks to be performed while achieving maximum efficiency. A worldwide network of sales agents and service partners guarantees direct contact with customers as well as direct spare parts supply. Looking back on a quite varied history, in particular when the company first started and the company founders had to cope with some setbacks, the Engcon group are now employing 200 staff reaching a turnover of about 90 million euros in 2016. Today, apart from at headquarters in Strömsund in central Sweden, tiltrotators are also mounted in Poznań in Poland to supply the Eastern European market. The company which started as a two men enterprise has now grown into the world leader for tiltrotators and their accessories. Engcon is still characterised by ingenuity and inventiveness more than 25 years after the company was first founded. At the end of 2016 Engcon presented the new locking system QSC, a safety relevant controlling system, which minimises the risk of pressing the wrong button or activating the wrong function when hitching the bucket or another tool to, or unhitching from, the quick hitch of the excavator.

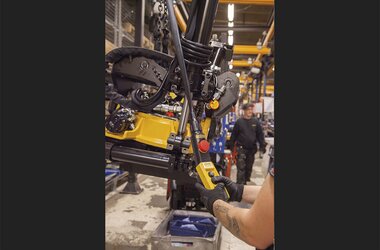

The first ABUS light-weight systems, mostly ABUS HB systems, were installed in the production, in the assembly line, and in the test area of Engcon as far back as 1999. These were crane systems with load capacities of 1 tonne each which have been operating for many years. Last year saw the installation of a further eight single girder crane systems EHB in the assembly hall with SWLs of 500 kg each. All eight systems feature two cranes each. EHB systems are known for their low dead weight, substantial suspension spacing, and smooth movability. It is easy for the crane user to move cranes and hoists manually. The crane systems for the assembly line have been fitted to a free standing portal structure. A portal structure is the ideal solution in case the HB crane system cannot be mounted to the ceiling while providing high flexibility if it should become necessary to reconfigure or expand an existing crane system.

Next to ABUS HB systems Engcon uses stationary mounted electric chain hoists and several wall jib cranes of the LW type as well as pillar jib cranes of the LS type in the lower load capacity spectrum of up to 1 tonne to serve individual work stations in particular in the test area. The Swedish subagency of ABUS, CarlHag AB, has been the reliable partner for Engcon for consultation, sales, and installation ever since the first crane was supplied. Maintenance and inspection of all cranes and hoists is carried out by one of CarlHag’s service stations.